Manufacturing Risk Insights: Preparing for a Product Recall

Whether it be vehicles, pharmaceuticals or food products, what might risk managers learn from mass media cover of product recalls? For manufacturers of all types of consumer goods, this might serve as a wake-up call to the potential impact of a product recall and a lesson in how to prepare for potential exposures.

Product recalls or contamination can easily cost millions. In addition to the physical expense of a recall, falling sales due to poor consumer confidence, brand rehabilitation expenses and potential legal actions may also contribute to long-term losses.

Despite recall frequency and the potential for extraordinary costs, most companies don’t adequately plan, prepare and practise for—or buy manufacturing insurance to protect against—product recall events. In addition to proper insurance covers, careful planning is essential in managing the risk of a recall.

Types of Exposure

There are two categories of exposure for a company faced with a product recall incident: first-party operational losses (losses incurred by your company) and third-party liability (losses to injured persons).

Much of the media attention goes to third-party losses, as naturally risks to innocent parties are the first to spring to mind when a product needs to be recalled. However, this often means your company's potential losses are often overlooked.

In addition to initial recall expenses, the potential long-term losses from the damage to a company’s reputation and loss of sales may continue for months or even years. Since these losses can be catastrophic, this article focuses on ways to manage first-party incident exposures.

Misconceptions and Considerations

It is a common misconception that product recall is covered under a general or product liability policy. Those covers do a good job of covering bodily injury and property damage, but generally exclude contamination and recall events. The addition of a product contamination or product recall policy protects your bottom line by covering the direct costs of recall, but transferring the risk is only one part of closing the recall exposure gap.

Regardless of size, every company offering consumer products—and those that offer products intended for commercial and industrial use—should establish solid product risk management policies and procedures for handling a recall or contamination event.

Understanding Three Basic Perils

It’s helpful to understand the three basic contamination perils when designing a risk management programme that provides the best protection for the least cost.

- Malicious tampering (intentional contamination) is prone to publicity, so it may seem common. In reality, malicious tampering is rare, but it tends to be a very severe loss. Managing this risk exposure can be difficult, as motives vary widely.

- Accidental contamination is an unintentional error in the manufacturing, packaging or storage of a product. This includes mislabelling of ingredients and contamination by a foreign object or chemical. This peril is the most common, but the majority of incidents are discovered prior to shipment. Therefore, these events receive very little publicity. Unlike malicious tampering, this peril has very high frequency but usually relatively low severity. While most accidental contaminations are small events, historically the largest losses have been due to accidental contaminations.

- Product extortion is the most difficult peril to characterise. Its frequency is between that of malicious tampering and accidental contamination. Its severity, however, is more difficult to quantify. Most extortions are amateurish hoaxes but may evolve into outright tampering cases, which can be very costly.

Pyramid Defence

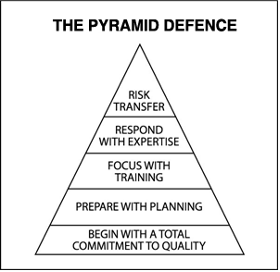

Think of your risk management plan as a pyramid that outlines a series of defences to counter the threat of a product incident. The first line of defence is the base of the pyramid. What actions can be taken to eliminate the majority of threats, such as unwanted bacteria, disgruntled employees, malfunctioning equipment, sloppy suppliers or lax testing? Put that in the first tier (bottom) of the pyramid. Any threats that escape elimination by the first tier should be addressed by the second, and so on. As the pyramid rises, the plan becomes more specific and more effective at isolating and eliminating product incident threats.

Tier 1: Begin with a total commitment to quality.

The good news is that most of what can be done to protect against a product incident occurs in the area of product quality assurance and control. Commitment to turning out the highest quality products day after day is the best countermeasure to the threat of a product recall crisis. This dedication to quality should be evident in every aspect of business, from manufacturing to marketing. The logic is simple: If the product can’t leave the plant in a contaminated state and the packaging is designed so that tampering is difficult to accomplish or obvious once done, the odds of experiencing a major incident are considerably reduced.

Tier 2: Prepare with a continuity plan.

It is essential to have a plan in place before a crisis arises. Research indicates that the first 48 hours of a major product incident are more crucial than the next 48 days. Every company should have a workable product recall and crisis management plan.

Tier 3: Focus with training.

Continuity plans aren’t useful if they haven’t been tested and honed under simulated conditions to ensure the plan works.

Tier 4: Respond with expertise and decisiveness.

Even with a good team and a good plan, there is a place in a recall crisis for professional consultants.

Tier 5: Transfer risk where possible.

Even the best companies who are prepared for a recall can suffer substantial financial losses. In spite of all precautions, a large-scale public recall may cost millions of pounds in increased expenditure, lost profits, lost inventory, lost shelf space and lost market share. If it comes to this, the last line of defence is a solid product recall insurance programme—one that indemnifies for the host of increased expenditures and losses in revenue that come with product withdrawals.

Product Recall Insurance

Insurance products for first-party losses caused by product tampering and contamination incidents are broadly labelled as product recall insurance. Product recall policies can help to cover the additional costs of a recall, including product loss, costs to withdraw the product from market, product disposal, product testing, overtime wages and crisis management—costs that can be devastating because they arise at a time when a company's revenues are typically hardest hit.

There are several cover forms, each designed to isolate some component of first-party product exposure. Work with the manufacturing insurance experts at Digney Grant to ensure your product recall policy provides indemnity for:

- Recall expense. This out-of-pocket expense is associated with executing a large-scale product withdrawal. It includes costs like extra temporary employees, overtime, public safety messages, special testing and handling, destruction and disposal costs and crisis management and/or PR consulting fees.

- Replacement cost. As the name implies, this is the cost of replacing any product that had to be destroyed. This includes the cost of materials, labour and overhead directly associated with producing the product.

- Lost profits. This indemnifies the insured for profits that would have been earned on the withdrawn products and also for profits that would have been earned on future product sales but which were not earned because of resultant future sales declines. This is usually limited to a specified time period.

- Brand rehabilitation expense. Most underwriters will also indemnify the insured for necessary rehabilitation of the recalled product’s consumer image. This includes costs like extra advertising, increased expenditure to rush a new product to market and special promotions to rebuild public trust in the manufacturer and its products.

In addition to transferring risk, thorough risk management practices are essential to minimise the exposure and the cost of a recall event. The product recall insurance marketplace is highly specialised. Our manufacturing insurance experts at ABL Group can help secure the cover you need and collaborate with you to develop a business continuity plan that meets your needs.